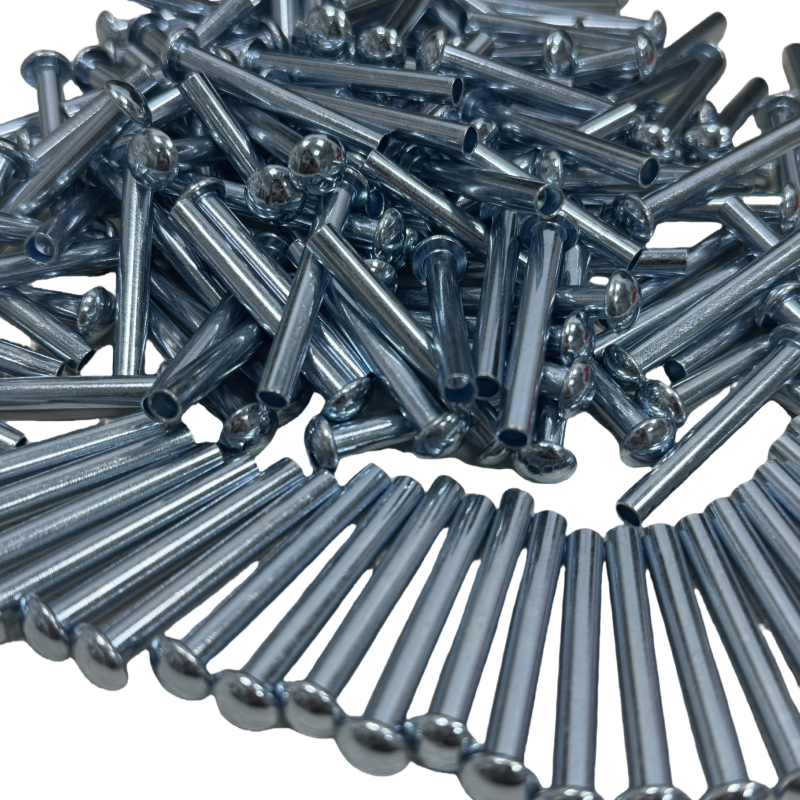

Mechanical plating forms a dense coating on the surface of rivets through a cold welding process of metal microparticles. Its unique deposition method results in a coating with uniform granular protrusions.

- +86-13926955418

- py_duke@163.com

- Building 3A Dongzhen industrial Park the third industrial ZoneNanlang Town, Zhongshan